beatus

facade

SERVICES

We focus on excellent service and project management, providing personalized architectural solutions to our clients. We offer transparent and fair pricing, strictly control the production process to ensure product quality. We also closely monitor transportation, installation, and after-sales support, ensuring smooth project progress and addressing customer issues. Our goal is to become a trusted partner for our clients.

Project

Management

Team

The project management team comprises 20 members, with 8 project managers,

3 of whom have over 10 years of experience. We are actively hiring more skilled professionals to enhance our team.

Project

Divide projects into different types: Scale: Large/Medium/Small Type: Residential/Commercial/Public/Mixed-use, etc. Establish a project database to improve efficiency and cost management.

Management

This process is crucial for the door and window industry as it involves various aspects of work, including design, procurement, production, transportation, installation, and after-sales service. Effective project management can enhance work efficiency, reduce costs, ensure quality, mitigate risks, thereby improving customer satisfaction and company competitiveness.

Management

Process

Requirement Confirmation and Planning Phase:

-

Analyze customer requirements and confirm project scope and technical specifications.

-

Develop project plan and schedule, outlining tasks and milestones.

Design and Proposal Development Phase:

-

Responsible for door and window design, ensuring compliance with Australian standards and customer requirements.

-

Develop detailed manufacturing plans and construction drawings, including material selection and production processes.

Supply Chain Management and Procurement Phase:

-

Ensure smooth supply chain and timely procurement of raw materials and components.

-

Monitor supplier delivery times and quality to ensure production schedules are not affected.

Production Manufacturing and Quality Control Phase:

-

Arrange production manufacturing to ensure product quality and delivery times.

-

Implement strict quality control measures to ensure products meet standards and customer requirements.

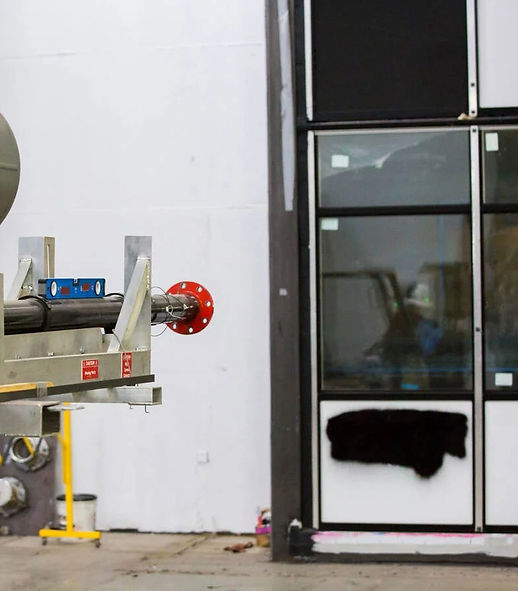

Transportation and Installation Phase:

-

Coordinate transportation arrangements to ensure safe delivery of products to the construction site.

-

Supervise installation teams for on-site installation, ensuring proper functionality and integrity of doors and windows.

After-Sales Service and Customer Satisfaction Survey:

-

Provide after-sales service support to address customer issues during use.

-

Conduct regular customer satisfaction surveys, collect feedback, and continuously improve service quality.

Management

Indicator

These include project plan completion, achievement of key milestones, task completion rates, etc., used to measure whether the project is progressing as planned.

01Cost Indicators

These include project budget execution, actual costs vs. budget variances, cost performance index, etc., used to assess the project's cost control.

02Quality Indicators

These include quality assessment of products or services, problem resolution speed, defect rates, etc., used to measure the quality level of project deliverables.

03Risk Indicators

These include risk identification and assessment, execution of risk response plans, effectiveness of risk mitigation, etc., used to evaluate the effectiveness of risk management in the project.

04Resource Utilization Rates

These include utilization rates of human resources, material resources, etc., used to assess the effective utilization of project resources.

05Customer Satisfaction

These include customer feedback, complaint handling, results of customer satisfaction surveys, etc., used to measure customer satisfaction with project deliverables.

06Performance Evaluation

These include performance evaluation of the project team, leadership assessment, teamwork, etc., used to assess the performance of the project team.

Design

Beatus facade has over 10 designers, including specialized designers of aluminum products such as doors, windows, and railings, providing end-to-end services from design concepts to production implementation.

Design Concepts

Based on customer requirements and project specifications, we design the overall layout and style of doors and windows, including exterior design, size planning, and material selection.

Drawing Creation

Using CAD and other design software, we create detailed drawings of doors and windows, including floor plans, elevations, and cross-sections, ensuring that the design meets specifications and standards.

Material Selection

We choose suitable materials based on project requirements and budget, aiming to reduce costs and improve efficiency.

Inspection

We have over 60 pieces of equipment and offer more than 140 testing items to provide scientific data support for product development and applications. We routinely

provide the following testing services:

□

□

□

□

Three-Performance Testing

Repeated Opening and Closing Testing

Sound Insulation Testing

Thermal Insulation Testing

If you need additional testing reports, please feel free to inquire.

Packing & Transport

Pre-assembly

Before shipment, the door and window panels are pre-assembled to improve installation efficiency and reduce labor costs.

Iron frame packaging

First, use foam packaging to reduce collisions between glass and aluminum. Then use an iron frame to secure the panels, reducing impacts during shipping.

Labeling

We have a standard labeling system where products are categorized and packaged according to different regional labels, further enhancing installation efficiency.